How to correctly distinguish LPC II

So we have already learned why it sometimes works and sometimes it doesn’t. Because I started with LPC in the socialism time, in ZEZ VVZ Liberec, it worked for me too. But in a few pieces. But the situation is different when we must make effective batches. That is, with a lot of steel pieces. That’s starting to be art. Perhaps that is why ALD and ECM have made their way to the top in the automotive industry. For example, ECM has 64 carburizing cells at Ford Motor Company’s Sharonville, Ohio Transmission Facility, or 39 additional carburizing cells at GKN Driveline in Newton, North Carolina.

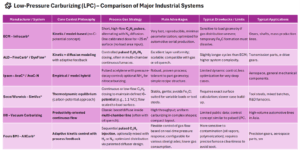

I tried to compile a comparison of individual LPC suppliers in terms of process control. And here is the result.

Because I personally only have ECM and SecoWarwick mapped, I have to let myself be carried away by the published information or my personal experiences for the others. The list does not include the Chinese companies SAMT and Fulcrum.

In any case, what I published in the first part has its justification. The secret is in the control of the atmosphere. ECM, due to its philosophy, has a unique feature in that I do not need to know the batch area, I do not control the partial pressure of the carbon but the carbon flux, and I have the best prerequisites for a high gradient between the atmosphere and the surface. The process will therefore be fast and reliable even for large batches with a large area of up to 25 m2.

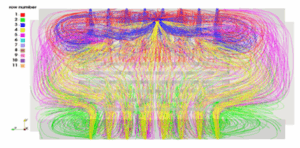

However, since the carbon potential must be the same throughout the furnace volume, the gas input must correspond to this. In order to carburize evenly, in addition to the fact that I need dozens of nozzles in the chamber, I also need their shape. The velocity of the gas and whether I am in the area of laminar or turbulent flow, and the total pressure, are important. The gas pressure control should be +/-0.05 mbar. Pulses longer than 120 s do not make sense, during this time the surface of the steel will be saturated so that there will be a zero gradient between the atmosphere and the surface of the batch.

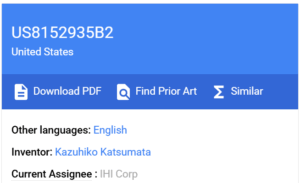

Although IHI calls its system “continuous vacuum carburizing”, like everyone else, it uses a saturation and diffusion period system. This can also be found in these patents. So the term probably has a different meaning than it seems to us. They didn’t let me into the IHI in Wilten, so I don’t have anything more to say about it. The fact that it works cannot be questioned

So much for the second chapter. In the third one, I will add the rest of the knowledge, but it will be more about the clogging of the furnace with physical contamination.

Jiří Stanislav

November 3, 2025