Stress relief annealing

Annealing to remove internal stress is one of the completely banal operations. The extent to which this thermal operation is necessary is decided by the designer and technologist. It is usually used after welding, repair-welding, EDM application, roughing machining, 3D printing etc.

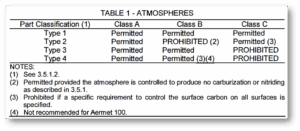

First of all, it must be said that it is a thermal process without recrystallization, below the temperature of AC1. Since it usually takes place at temperatures of 600-650 C, it depends on our requirement for the condition of the surface after this process. It is best to choose the atmosphere according to AMS 2759, where according to the additions for further machining, the parts are divided into 4 type categories (Type 1, 2, 3, 4), and 3 basic types of atmosphere are assigned to them Class A, B, C.

However, I still encounter an effort to circumvent or not carry out these processes, either in terms of time or finance, but often also because there is no proper understanding of this process. Since tension in the material is a “virtual” phenomenon that we cannot touch, which usually does not manifest itself externally, then it sometimes leads to the conclusion that it is not necessary.

An example is the production of moulds, where stress annealing should usually be included after roughing. But because this means one extra trip to the heat treatment shop, in many cases the tool shop sends the parts to the heat treatment with the requirement to “anneal, harden and temper 3 times”. As the classic would say, it’s futile, it’s futile, it’s futile ….

With the right procedure, it is necessary to

- Roughing machining

- Anneal

- Machined with hardening allowances

- Quench and temper

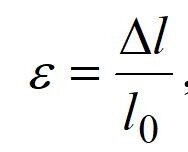

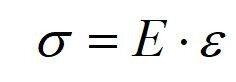

When roughing with high material removal rates, internal stress is introduced into the material. These can reach up to 200 to 500 MPa. Whether we are at the lower or upper limit depends on our method of machining. The literature states that we can release 80 to 90% of the stress through the thermal process. If we simplify it for the sake of illustration, we estimate that we will release, for example, 200 MPa of stress. What does this mean in practice? We will use classical equations to calculate the change in dimension.

- Young’s modulus of elasticity for steel is 210,000 MPa.

In our case, Ɛ = 200/210000 = 0.0009523. If we have a part with a length of 500 mm, then its change in dimension with respect to the change in tension will be 0.476 mm. That’s not a small amount.

If we proceed correctly, the deformation after quenching will be only and exclusively from the hardening process, i.e. from the volume changes and stresses that arise as a result of hardening. But if we don’t anneal, these phenomena will be superpositioned, and in the end we have some deformations, which we have nothing to blame on. Were they due to machining or were they due to hardening?

When roughing, we leave allowances of 3-5 mm. After annealing, we machine the surface with hardening allowances of 0.5 to 1 mm.

Similarly, we can talk about stress annealing after welding or repair-welding. Here the situation is even more complicated, because we have a number of structural changes in the so-called HAZ zone (Heat Affected Zone). Quite recently, I came across an expert opinion where the expert claims that not performing annealing to remove the stress after welding is okay, because the stress is reduced by only an order of magnitude. In numerical terms, it is from 500 MPa by 50 MPa, i.e. to 450 MPa.

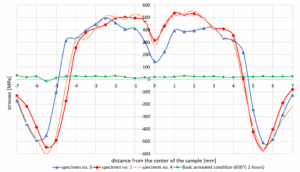

An example is this diagram from the publication https://www.mdpi.com/1996-1944/13/22/5289 [1]. The impact of annealing on stress is quite obvious and visible on the green curve. From 500 MPa tensile stress, we got to values of about 20 MPa. This is at 4% of the original stress.

[1] Experiments and Numerical Simulations of the Annealing Temperature Influence on the Residual Stresses Level in S700MC Steel Welded Elements, MDPI, 2020

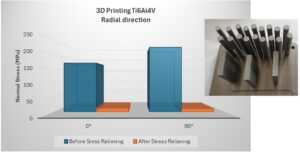

I have another example from our development of 3D printing of implants with Ti6Al4V. The effect of annealing on stress relief in Ti6Al4V printing is shown in the graph. We have reduced the stress to about 7% of the original state.

[2] Vliv hustoty energie a izostatického lisování za tepla na mikrostrukturu a poréznost slitiny Ti6Al4V připravené metodou laser powder bed fusion, Doc. Ing. Tomáš Čegan, PhD., přednáška na Czechimplant, 2025

From the above, it is clear that stress relief annealing makes sense and is technically justifiable. The fact that this condition is not visible at first glance does not mean that we can ignore it.

Jiří Stanislav

October 19, 2025