How are magnets made?

It’s a strange topic. When I started at ZEZ Praha, VVZ Liberec, I was in charge of the development of PVD technologies and the Leybold device with 4 planar magnetrons was available. Their magnetic field was created from 10×10 mm SmCo magnets. At first glance, it looked completely normal, but at second glance, when the magnets began to peel off the base plate after some time, the problem arose. Their strength was such that it pinched our fingers. So it is not only a magnet, but also a life-threatening .

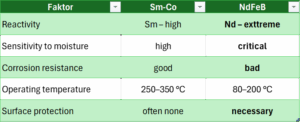

SmCo magnets offer the best ratio in terms of size, performance and resistance to high temperatures or adverse conditions. They are very resistant to corrosion and therefore do not require surface treatment. They can be used for temperatures up to 250-300 C, and are more stable than neodymium magnets (NdFeB).

But how are such magnets made?

I became interested in it only now, with the battle for the world’s reserves of rare elements. We must not only have these elements, but we must also learn to make these special magnets out of these elements. Both types of magnets will have similar process steps, but virtually everything must take place in a vacuum, due to the affinity of Nd and Sm for oxygen.

What is the procedure?

- Co and Sm powders are taken, they are melted in a vacuum induction melter. The blank is cast. Temperatures: approx. 1300–1500 °C, Atmosphere: high vacuum (10⁻³–10⁻⁵ mbar) orultra-pure If a magnet is made up of SmCo₅, it is a binary alloy. The alloying will be 35% Sm, 65% Co. If the magnet is made up of Sm₂Co₁₇, it will be a complex system with the addition of Cu and Fe. The chemical composition will be approximately Sm 25%, Co 60%, Fe 10-18%, Cu 3-8%. The sum must be 100.

- Now we need to make a powder with 3-10 μm grains from the casting. This is done by crushing, usually in a hydrogen atmosphere

- This is followed by Cold Isostatic Pressing (CIP) to obtain maximum density and crystallographic orientation

- The next, most important step is sintering in a vacuum furnace. Temperatures:

- SmCo₅: ~1100–1150 °C

- Sm₂Co₁₇: ~1180–1220 °C

- Atmosphere:

- vacuum 10⁻⁴–10⁻⁵ mbar or pure Argon

5. This is followed by controlled heat treatment (aging), typical of Sm₂CO₁₇:

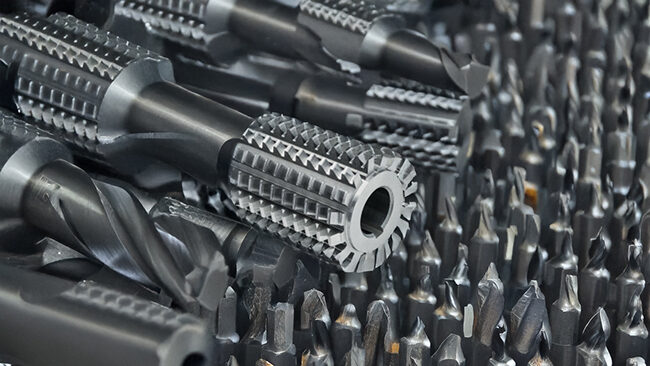

6. The last step is machining and possibly surface treatment.

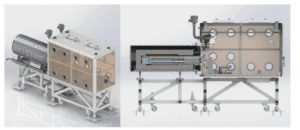

However, the powder produced must not come into contact with oxygen. Therefore, at the outlet of the device, there must be a chamber with an ultra-pure inert atmosphere (Ar, exceptionally H₂), typically O₂ < 1–5 ppm and H₂O < 1–5 ppm. Otherwise, the powder produced in this way, with a huge area, may catch fire due to accelerated oxidation.

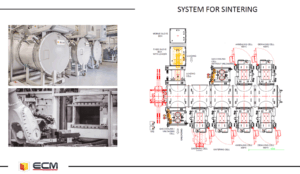

Subsequent sintering can take place in various single-chamber furnaces, but ECM Technologies can also supply equipment, they perform all operations comprehensively in one FLEX system.

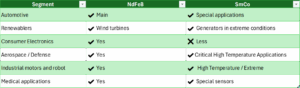

I don’t know if this is a challenge for the expansion of vacuum technologies in CZ and SK. In any case, it’s a big topic, because these magnets are needed practically everywhere today.

And the growth potential? 8-9% per annum until 2030, with the return transfer from Asia quite possibly swinging these numbers.

If you are interested in learning more, please do not hesitate to contact me.

Jiří Stanislav

January 10, 2026