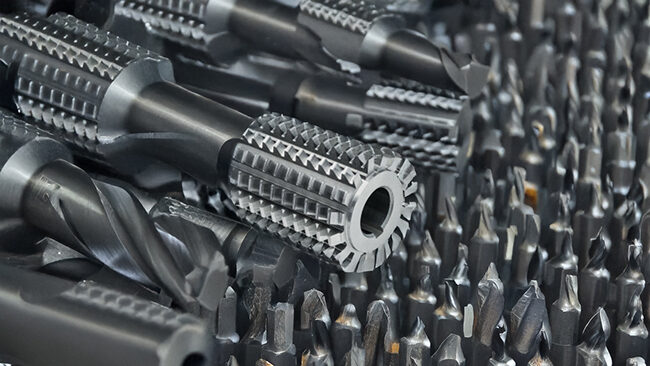

NANO 600 – tool solutions

A special category of vacuum heat treatment is high-speed steels, whether conventionally produced or from powder metallurgy (PM). Although these processes are seemingly simple, their complexity lies in the fact that we try to do them in classic vacuum furnaces, i.e. furnaces with a minimum size of 600×900 mm, 800 kg charge. This is not a good way. Since these steels cannot be optimally combined in one charge, mainly due to the mismatch in austenitization temperature, the charges are usually small and uneconomical. To tell the truth, at Bodycote we have essentially given up this business, and if possible, we have had it hardened by high-speed steel specialists.

Another finding was that if the quenching plant does not pay attention to this problem in detail, the quenching and tempering curves from the steel suppliers do not work as they expect, and usually the problem arises that the required hardness or toughness is not achieved. See, for example, the publication of Klára Tesárková [1].

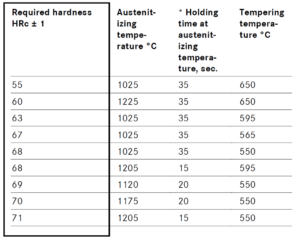

The table below shows the heat treatment prescription for powder steel CPM® REX 121. To achieve the required hardness, a combination of quenching temperature and tempering temperature is necessary. This is quite a serious problem when the third parameter affecting the result is time. Almost insoluble in the conditions of a commercial vacuum quenching plant and combined charges.

That is why salt baths are still considered the ideal solution for HSS. Short heating times, perfect homogeneity of the salt bath, the possibility of stepwise heating, isothermal or bainitic hardening, high cooling rate with the exclusion of the eutectic carbide precipitation area, minimal change in austenitic grain, etc.

Fig. 1 – Specification for PM CPM® REX 121

Typical representatives of the HSS steel series are [2]:

- M2: Tough, good wear resistance, and good red hardness. Other names are: HS 6-5-2, 1.3343, S600 Steel, E M2, REX M2®, SKH 51, P6M5, and 6-6.

- M3:Good wear resistance and commonly used in form tools. Also known as: REX M3-1®, PM M3, and Corsair.

- M4: Excellent abrasion resistance. Other names are: HS 6-5-4, E M4, SKH 54, and Stark.

- M7: Widely used for drills. Known as 1.3348, HS 2-9-2, E M7, REX M7®, SKH 57, and Tatmo-VN.

- M42: Allows higher cutting speeds. Also known as: 1.3247, HS 2-10-1-8, S500, E M42, REX M42®, and Dynamax.

- PM M4: Excellent impact toughness and bend strength. Other names are: CPM REX M4 steel®, ASP 2004, and S690.

- PM T15: Provides long life. Known as: 1.3202, ASP 2015, CPM T15®, SKH 10, HS 12-0-5-5, and S399.

- PM A11: Good wear resistance: Other names are: CPM® 10V® and AISI A11.

- PM M48:Offers higher cutting speeds. Known as: 1.3207, CPM REX 76®, ASP 2048, HS 10-5-3-9, and SKH 57

Some of them require precise control of temperatures and times to achieve the desired results. In particular, M42 (1.3247, HS 2-10-1-8, S500, E M42, REX M42®) and T15 (1.3202, ASP 2015, CPM T15®, SKH 10, HS 12-0-5-5, and S399) have very narrow heat treatment windows due to the higher cobalt content.

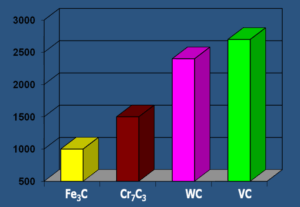

An important condition for a good result is also the control of the amount and structure of carbides, the formation of which during the heat treatment process significantly affects the resulting properties of the tool.

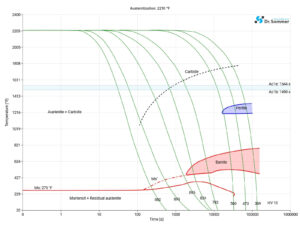

Fig. 2 and 3 – CCT diagram for steel 1.3343 with emphasis on the carbide precipitation area and hardness in HV of various types of carbides present in powder in HSS

The quenching of HSS and PM HSS steels is therefore specific in that during the actual austenitization we only need to have short temperature holding times, so as to heat the tool in its full cross-section, but so that at such high temperatures we do not coarsen the grain. For cutting applications it should be 9 and finer.

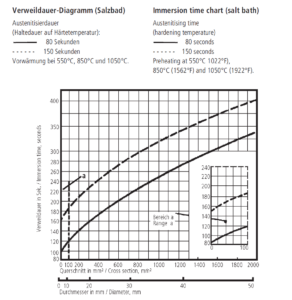

If we harden in salt, these times are in seconds (Fig. No. 10). With vacuum furnaces it is worse, because firstly we have temperature uniformity dependent on the furnace class, in Class 2 it is +/- 5 °C, and secondly due to the heterogeneity of heating in a large space it is difficult to maintain the same parameters throughout the batch. The same applies to the dissolution of carbides.

However, with the need for coating technologies (PVD, CVD), the demands on surface cleanliness are increasing, and that is why there is an effort to transfer these processes to vacuum. A typical surface for salt hardening is shown in Figure 4. Even if we try to sandblast the surface, we will never achieve a condition suitable for PVD coatings. I have extensive experience with this when we compared the service life of formed drills (Zbrojovka Vsetín) and fully ground drills from a full profile (ZPS Zlín) in the past. Such a surface after salt hardening can only be repaired by 100% grinding off the affected layer.

Fig. 4 – Example of surface after salt bath hardening

Fig. 5 – Examples of coated tools from the Czech Coating presentation [4]

From this point of view, ECM NANO appears to be an optimal compromise. As in the salt bath, here we load the charge into a heated chamber, and since its volume is minimal, the heating rate will be close to the heating rate in salt baths. The same applies to quenching in 20 bar nitrogen.

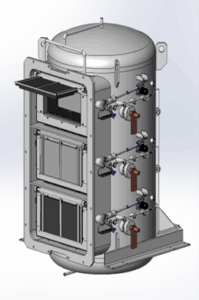

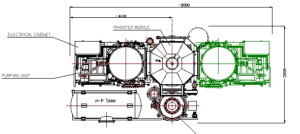

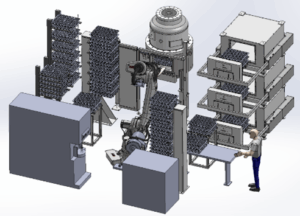

The basis of the NANO system solution is a vertical transport chamber. Modules with heating chambers are connected to this chamber. These modules can be one or two. Heating chambers can be 150, 250 mm or 400 mm high. At a height of 150 mm, there can be 6 of them above each other, at a height of 250 and 400 mm there are always 3. In the first case, we can have a device with up to 12 heating chambers, in the second with six. The grid size is 500×600 mm and the maximum weight is 100 kg for all typo dimensions.

Fig. 6 and 7 – View of the vertical transport chamber and column structure with heating chambers

Fig. 8 – View of the device, movement indicates the method of maintenance access to both the elevator and the heating chambers

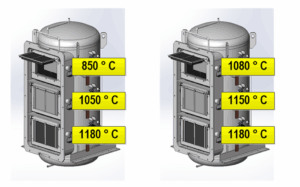

If we have the NANO 600 configuration, we have 2×3 heating chambers at our disposal. Each of them can be at a different temperature, up to 1250 °C. This means that different types of HSS can be processed simultaneously in one device, or even one type of steel from different temperatures. However, it is also possible to imitate stepwise preheating, as is the case with salt baths or in a single-chamber vacuum furnace.

Fig. 9 – Example of possible use of heating chambers a) for step heating b) for different austenitizing temperatures

Fig. 10 – Austenitization times in a salt bath from Bohler [3]

This configuration allows modeling of HSS heat treatment processes as in a salt bath, but in this case it is a fully vacuum process. If austenitization times for HSS parts hardened in a salt bath are recommended in the order of seconds, then only a NANO type device allows achieving similar parameters [3].

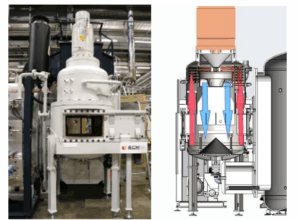

After austenitization, quenching in a nitrogen flow of up to 20 bar follows. Cooling rates are up to 50 °C/s, so the batch can be cooled to room temperature theoretically in 24 seconds. In practice, it will be in minutes, depending on the structure of the parts in the batch. The minimum cycle time between 2 subsequent quenchings is 7 minutes. However, this time also includes other steps, such as opening and closing the chamber door, etc. The time for the batch to move from the heating chamber to the quenching chamber is up to 30 seconds.

Fig. 11 – Quenching cell

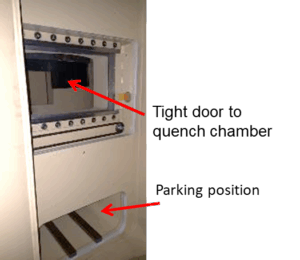

Fig. 12 – View of the entrance to the quenching cell and the parking space

After hardening, the batch is taken out of the device for further operations. Loading and unloading from the device is through the hardening chamber. Inside this part of the device there is also one parking position in case it is necessary to wait inside the device for planning reasons (Fig. 12)

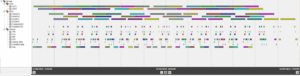

Fig. 13 – A system for planning the course of the batch in the device, taking into account the cycle time, type of part and type of thermal process

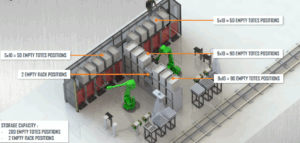

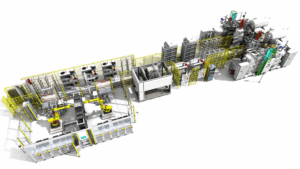

Other operations take place outside the NANO 600, but are assembled into a fully automatic line. This can contain everything according to the customer’s wishes. Furnaces for tempering of any type, freezing, washing, parking positions, but also full robotization of batch preparation and its unloading. Everything is then controlled by the planning SW according to Fig. 13.

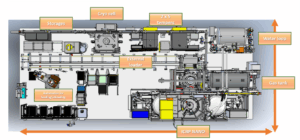

Fig. 14 – Typical layout

To maintain the cleanliness of the surface after hardening, we must have appropriate tempering furnaces. Up to 450 C°, they can be without a protective atmosphere, above this temperature they must have a protective atmosphere.

Fig. 15 and 16 – Three-deck furnace for tempering under protective atmosphere, N2 or N2+5%H2.

Since practically all types of HSS steel require 3 temperings, sometimes even 4, the number of tempering furnaces must also correspond to the hardening cycle. This must be assessed individually by each investor. However, the tempering temperature options are the same as for heating chambers. Each can be at a different temperature. Since we have to cool the parts to 50 °C between individual tempering cycles, this phase of the process must also be under a protective atmosphere. The tempering furnace must therefore have rapid cooling.

However, it is also possible to imagine that a classic vacuum tempering furnace, with vertically or horizontally moving doors, will be integrated into the line; for other applications, such as LPC, tempering furnaces without a protective atmosphere will be perfectly sufficient.

Fig. 17 – Three-deck low-temperature tempering furnaces

Fig. 18 and 19 – Layout NANO 600

And what about possible robotization? Here are some examples.

Fig. 20, 21, 22, 24 –Robotization example

What to say in conclusion. NANO 600 is an amazing solution with high applicability, variability and reproducibility. It is a device whose productivity is comparable to large batch furnaces, but at the same time it provides a unique solution for reliable processing of batches up to 100 kg. Today it is no longer tied only to quenching in a gas stream, it also has a quenching module with oil quenching. In combination with LPC, it is therefore a large tool, capable of containing a large portion of heat treatment, in an all-in-one style.

Jiří Stanislav

January 14, 2026