How to check the input material on die casting dies

On the side of die casting tool manufacturers, a permanent problem is that they do not consider input material control to be so important as to deal with it more. This is understandable, because it’s not their profession, they don’t have the equipment or the human staff to do it, it’s delaying, and it’s worth the money. They prefer to rely on the credibility of the material quality assertion and documentation from the steel supplier because it is easier.

However, if the tool does not have the required service life or is claimed, the need for information on the input quality of the steel is so important that a guilt dispute between the steel supplier, the tool shop or the heat treater cannot be resolved without it. I can confirm this in person from litigation, to which I was invited as a forensic expert.

According to Nadca 207, input material tests are mandatory for all inserts manufactured in Class 1 or Class 2, the only difference being that for Class 1, additional impact tests are required. What does it mean?

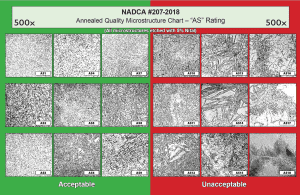

All purchased material must be tested metallographically for the acceptability of the delivered structure after annealing according to Nadca 207 rating maps, for primary carbides detection, cleanliness, grain size, microbanding, but only for Class 1 are impact tests mandatory.

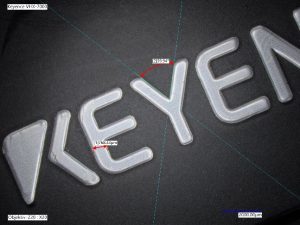

How to get out of it? Basically, it doesn’t have to be so demanding, nor unsolvable, if we have the right equipment. I had the pleasure to get acquainted with a digital microscope from the company Keyence, type VHX-7000. It is a device that allows a familiar person to perform a metallographic inspection directly in the hall of the tool shop. The device does not even have to be in the form shown in Figure 1, ie with a fixed stand. This key, ie the digital lens itself, can be portable, placed on a handling arm with a magnetically clamped cube (Fig. No. 2). In both cases, it is then connected with a cable in exactly the same way to the computer with the display. Measurements can therefore be performed anywhere, in a metallurgical warehouse, at a machining center, at an inspection. The connecting cable is not a limit either, it can be up to 20 m long.

Fig. 1 – Keyence VHX-7000 as a laboratory microscope

Fig. 2 – Holder for working measurements directly on the hall of the tool shop

If the tool shop is equipped in this way, there is nothing easier than to polish the surface on the supplied material, etch it with Nital, and then display the surface at a magnification of 500x. We will compare what we will see with the rating maps of annealed structures of Nadca 207. If we are in the green area, we can release the material for machining, if in the red area, it is better to return the material immediately and complain. We are able to complete the entire process from polishing to image capture in 15 to 20 minutes.

Fig. 3 – Nadca 207 rating map for annealed hot work steel with acceptable and unacceptable microstructures

Fig. 4 – Example of capturing an image directly from the hand

Fig. 5 – The image of the fabric taken by the method according to Fig. No. 3

The microscope can be equipped with various objectives, but because we need a magnification of 500x, we offer, for example, a lens VH-Z10UR / Z100UT with a range of 100 to 1000x.

But because the device has other amazing features, you can see its use in the manufacture of tools and for other activities. E.g. to check the removal of the remelted white layer after EDM, to check the quality of the polished surface, to check the patterned surface, to check the venting of the mold or to measure the dimensions of details (Fig. No. 6), which we are not able to measure by other means. There are many applications. Lenses have a large depth of field, which is also digitally correctable, so it is possible to display and measure shapes that would otherwise be difficult to analyze (Fig. No. 7)

But because the device has other amazing features, you can be convinced of its use in the manufacture of tools and for other activities. E.g. to control the removal of the remelted white layer after EDM, to control the quality of the polished surface, to control the patterned surface, to control the venting of the die or to measure the dimensions of details (Fig. No. 6), which we are not able to measure by other means. There are many applications. The lenses have a large depth of sharpness, which is also digitally correctable, so it is possible to display and measure shapes that would otherwise be difficult to analyze (Fig. No. 7)

Fig. 6 – Example of measuring dimensions and angles

Fig. 7 – Example of capturing an image of connector pins with a large depth of sharpness

If we return to the entry control according to Nadca 207, we have two variants. Either we have an additional coupon for samples for impact tests (processing Class 1), or we only have our own block of material from the steel supplier (processing Class 2).

In the first case, we analyze only the coupon material, which is a plate measuring 64x152x16 mm (2½ “x 6“ x 5/8 “), ready for future impact tests. We could do them later, but we can also do this by archiving this sample of material, marked with a serial number, and only returning to it if there is a dispute over quality. Because hidden defects can be claimed within two years of receiving the material or part from the heat treater, this is also the minimum time for which we should archive these samples.

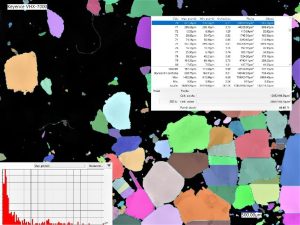

If we also need information about grain size, we must follow Nadca 207 and ASTM E112. However, it is also possible to cut a piece and let it oxidize in an annealing furnace at 960 C / 30 minutes, followed by cooling in water. The 10×10 mm area is then polished and placed under our digital microscope. The microscope can analyze the image at 100x magnification itself, automatically, so even determining the grain size is not a big problem for this instrument.

Fig. 8 – Test of the size and number of grains for table salts, performed as part of the demonstration of the microscope

If we do not have coupons for impact tests, we must perform an input inspection of the material directly on the supplied block. The procedure is essentially the same as in the first case. A surface is polished on the block of material, etched with Nital and the image is taken. In this case, however, we cannot archive our own material, we do not have it, we only store an image of the structure taken with this digital microscope in the archive.

But even this is a big step forward, because we have at least some certainties that the material is OK at the entrance and does not show major defects, reducing the resistance to thermal fatigue. In the event of future disputes, even this can have great weight for deciding on the causes of defects.

The Keyence digital microscope is a great device that significantly solves the problem of tool shops with input material control. Its application can be much wider in the production of tools of any type.

6th November 2021

Jiří Stanislav