Vacuum furnace and its contamination

Vacuum furnace maintenance is an important part of vacuum processes. If everything is working, we tend to do nothing. However, as soon as a problem appears, e.g. in the coloring of components, failure to reach starting pressure, then our nervousness increases exponentially and we begin to wonder where the mistake happened. To avoid this, we must start with prevention.

ISO 20431:2023, Heat Treatment, Control of Quality

- Recommendation V4: furnace leak test must be performed once a month, for aerospace parts once a week. For special applications, always before starting the process.

- Recommendation V5: leakage should not be higher than 4 Pa/hour, except for titanium alloys, where 2 Pa/hour is allowed

- Recommendation V6: The dew point of the gases used (N2, Ar) should be continuously monitored with appropriate alarm settings when the values are exceeded. Its value should be below minus 60 C

AMS 2769, Heat Treatment of Parts in Vacuum

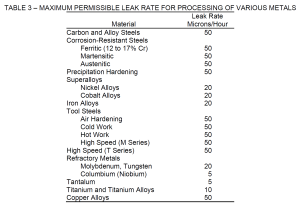

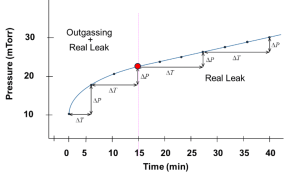

- Point 3.1.1.3 – The flow rate should not exceed the values from Table no. 3. Unit 1 Micron = 1 mTorr = 0.133 Pa. 50 Microns/hour is therefore a value of 6.65 Pa/hour, 20 Microns is a value of 2.66 Pa.

- The leak test can be replaced by a product contamination test. This test should be performed weekly, except for sensitive products, when testing with a higher frequency is recommended

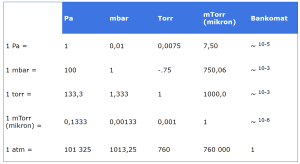

The leak test itself is described in such a way that the vacuum furnace is evacuated when cold to the lowest possible pressure, less than 50 Microns = 6.65 Pa, and then the vacuum pumps are disconnected and the entire furnace is closed at all inlet valves. The pressure increase over time is measured and recorded. Since in the first phase the pressure growth is influenced by the desorption of the furnace, the leak curve has an exponential character. There is a superposition of the pressure increase from the furnace leak and from the desorption. Only from the moment when the curve becomes linear we start calculating the leak rate (red point).

The resulting leak rate is calculated from the formula qL = ∆p * V/ time, where ∆p is the change in pressure over the controlled time period, V is the volume of the vacuum vessel in liters (usually given in the technical specification of the furnace) and time in hours.

If everything is OK, there is nothing to worry about. But a worse situation occurs when we do not reach the required values. For a number of processes there is a known limitation under which conditions the cycle can no longer be started. This is especially true for applications in the aerospace industry, for the processing of titanium alloys or for steels with a high chromium content with a high affinity for oxygen. So, until we fix the leaks, we can’t continue processing.

If we are not sure about the desorption of the furnace, we need to do it before we start looking for leaks. We heat the oven to 1,100 C with a maximally achievable vacuum, with a delay of 2 to 4 hours, and then let it cool down on its own while the vacuum chamber is continuously pumped. All absorbed gas molecules should thus get out of the furnace through the pumping system.

And how to proceed further? Above all, it is necessary to keep a detailed maintenance book of the furnace. There should be records of all actions that have recently been carried out on the furnace. E.g. replacement of the thermocouple, removal of the sealing ring of the door, disconnection and connection of various valves, control gauges, repair of feedthrough for the electrical supply to the heating, etc. We can then perform resealing of all surfaces according to the maintenance book of the furnace in successive steps.

If we exhaust these options and there is no improvement, we need to start looking for leaks outside of these records. The first places at risk are bellows, places where vibrations occur on the furnace, i.e. joints around vacuum pumps, or where there are movable piston rods of pneumatic cylinders entering the furnace, rotary bearings, e.g. the movement of closing flaps, etc. High temperature-stressed places can also be a source potential leak.

Once we have identified the leak, we can begin resealing. First, however, it is necessary to clean with a vacuum cleaner all dust particles and dirt from the working chamber. These are swirled in the furnace mainly during quenching in the gas stream and can be a problem in the subsequent process.

When checking the sealing surfaces, the best detection of dirt on the sealing surfaces is the human finger. It can detect dust particles even of sub-micron size. The sealing surfaces must therefore be cleaned and freed of both grease and dust particles. This is best done with technical alcohol and a microfiber cloth that leaves no hair behind. Subsequently, the surfaces are coated with a thin layer of silicone vaseline, which is able to even out minor unevenness of the sealing surface.

Technical alcohol has another advantage. If we don’t have a helium leak detector, we can use alcohol to find the biggest leaks. As soon as the alcohol evaporates on the surface, the alcohol vapors have a great penetration into the vacuum chamber, which is manifested by a temporary increase in pressure. But if alcohol is not enough, it is necessary to have a helium leak detector available.

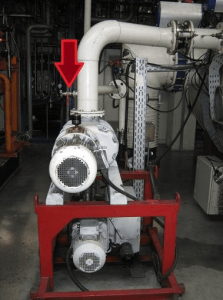

The location of the helium leak detector connection is important. On the one hand, we need to ensure a certain minimum pressure for the leak detector, on the other hand, we must be sure that we will be able to detect any helium penetration in the direction of its flow in the furnace. Usually, therefore, the connection point is just above the Roots pump, where both conditions are met. In order to be able to connect the leak detector while the furnace is running, the gas-tight shut-off tap must also be part of the connection. If we don’t have it there, we can put on air the entire furnace when connecting the leak detector.

The method of finding sources of leakage is a big science and requires a systematic approach. The problem is not only the high permeability of helium, but above all the fact that in the case of blowing a potential leak, we will also affect the near or far surroundings. It may then appear that we have found the leak, but it will actually be completely different from the place being searched. So we look for one place, and then cover it with PVC foil and sealing tape. We have to rule out the fact that a place that has already been inspected will not affect us for further leaks. A break of several minutes must also be included between the individual steps in order to give the helium a chance to disperse throughout the production hall.

Because helium is lighter than air, we usually start looking for leaks from the top down so as not to affect the connections below with helium. In any case, we must prepare for the fact that this process of finding leaks can take hours and the result may not always be positive.

If the leak is, for example, in the leakage of the nitrogen supply valve, then the only way to detect this leak is to disconnect the supply pipe and inject helium directly into the valve. It’s the same with water leaks, from the water exchanger, from the pores in the double wall of the furnace casing, etc. Here, every piece of advice is expensive, however, this can also be done in the case of systematic exclusion of places where there is no leak.

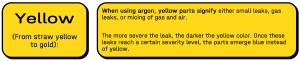

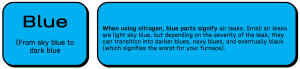

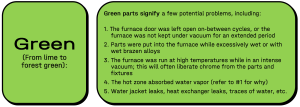

However, we can partially follow the color of the oven. Janusz Kowalewski from the Ipsen company has developed a very interesting analysis on this topic.

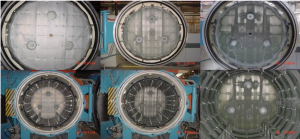

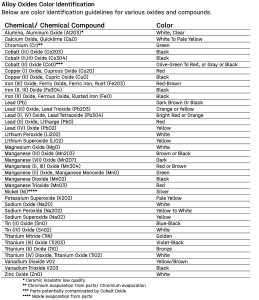

Examples of changing the color of the interior of the heat chamber are in the picture. In the case of chromium evaporation, the chamber will over time be dark green in color, in the case of copper evaporation during soldering it will be red in color, in the case of water penetration into the furnace, we will have reddish-brown or even black spots.

The list of all variants and colors is in the following table.

Since the vacuum furnace is a highly sensitive device precisely to the presence of oxygen from the air or water vapor, we have to get used to certain rules. First of all, it is necessary to have a furnace, if it is not necessary to start or unload the batch, to have it permanently under vacuum. Furnace operators must take this into account and once the batch is removed from the furnace, the furnace door must be closed and the furnace evacuated. And even if the delay between cycles is longer than 15 minutes. This especially applies to furnaces with graphite. If we have furnaces with molybdenum, the absorption of atmospheric moisture and other gas molecules will not be so sensitive to the short-term opening of the furnace, but even then we must take into account that atmospheric moisture from the surroundings can get into the insulation of the furnace.

As mentioned above, keeping the furnace in working condition requires a lot of systematicity. Both in the periodic performance of leak tests and in keeping records of all interventions on the furnace that may lead to the creation of a potential leak.

[1] The Impact of Contamination in Vacuum Furnace during Heat Treatment and How to Prevent it, Ipsen, Janusz Kowalewski, Japan, Osaka, 6/2023

[2] AMS 2759, Heat Treatment of Parts in Vacuum

[3] ISO 20431:2023, Heat Treatment, Quality Control

Jiří Stanislav

04. listopadu 2023