Euroguss 2026

So I went to Nuremberg for Euroguss 2026. I was curious about where we had moved with GIGA Casting, but especially with the production of GIGA dies for this technology. Let’s be honest, I was a little disappointed. Foundries of all kinds prevailed, there were only a few toolmakers. The Czech representation here was concentrated in one stand, where Kovolit, Kovolis, ALW, AS-Casting, Motor Jikov, Alutex or ČZ Strakonice were present.

Of the steel manufacturers, I found only Kind & Co and Bohler/Uddeholm.

Of the more important toolmakers, only M.C.S Facchetti from Italy, HTS Technology Group from Germany, and Kejia Mould Base, the Chinese manufacturer of GIGA dies, were represented. I have had information about M.C.S Facchetti for a long time, part of the tool production is also an internal heat treatment shop, with furnaces from TAV Vacuum Furnaces. I heard about the Chinese for the first time. But what disappointed me was their choice of steel. Frames 1.2738, 1.2312, die inserts of H11, H13. Seemingly the same materials as ours, but in my opinion it is not enough for GIGA dies. So something was probably not said. But Dievar is said to be expensive.

When I stopped by the IDRA stand with a question about GIGA dies for their GIGA presses, they only told me that each customer solves their GIGA dies themselves. When asked who will produce tools for VOLVO Košice, they just shrugged their shoulders.

But everyone unanimously claimed that they work according to Nadca 207. That’s at least something. At M.C.S Facchetti I learned that they don’t see it as a problem, even if the basic insert is huge, that piece of iron that causes a production problem in terms of cooling, thermal fatigue, etc., is produced as a partial small insert. That is why the problem of heat treatment of large parts is supposedly not so serious. And moreover, the largest parts are said to be up to 400 mm thick, so hardening will be fine. In the first case, I would agree, it will be about intelligent die division, in the second case, hardening parts with a thickness of 400 mm will be a problem, especially with steels of the H11, H13 type. We cannot avoid the area of precipitation of eutectic carbides.

However, M.C.S Facchetti’s statement does not match Tesla’s claim that the lifespan of the GIGA die is from 30 to 70 thousand pieces. That is simply not enough, and it is on these numbers that the Nadca 207 was created. Both GM and FMC considered this to be an insufficient lifespan, and wanted to increase it to 100 thousand pieces per die.

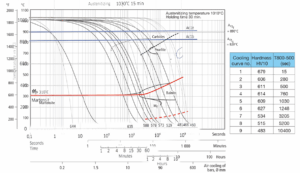

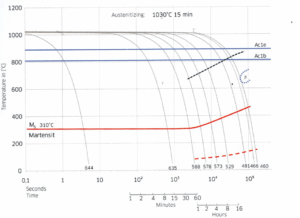

In the end, Kind & Co made me the greatest joy with the new MK1 material. From their documents, it looks like it is steel, even better than Dievar. See comparison of their CCT diagrams.

Dievar on the left, MK1 on the right

At the same time, they claim that their company’s heat treatment shop will be equipped with a new 8000 kg vacuum furnace this year, with dimensions of 1200x1200x2500 mm, 15 bar, heating power 600 kW, turbine power 650 kW, fully in accordance with Nadca 207. This is good information for those who want to get into GIGA dies.

Strangely enough, I did not find Daido Steel or their Daido GIGA steel at the fair. But it will probably not be too far from MK1 steel or vice versa.

The overall impression is neutral. No major surprises. Although dies production for HPDC exists, I have not seen anything here that would lead me to improve or change my thinking. On the contrary, everything is going on in the same old way. This is not entirely good, because practically all foundries have a problem with the life of their tools. And even though everyone is talking about Nadca 207, it’s like talking about ISO 9001. Yes, we have that. And what does it say? Well, I don’t really know, I have to go and see…

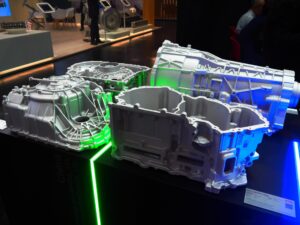

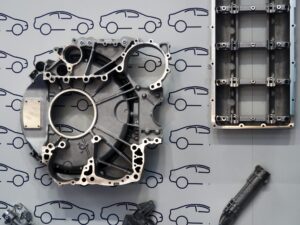

And here are a few more pictures

Jiří Stanislav

January 15, 2026